Services

Alongside their products, BCSA GEAR has acquired experience in many fields and developed speciality teams that are made available to its customers. We offer services in system balancing, vibration analysis and maintenance.

Read More

Balancing of rotating parts

BCSA GEAR has the competence and the means required to carry out accurate balancing on rotating parts. This one of the essential parameters for controlling the reliability of machines with high rotation speeds.

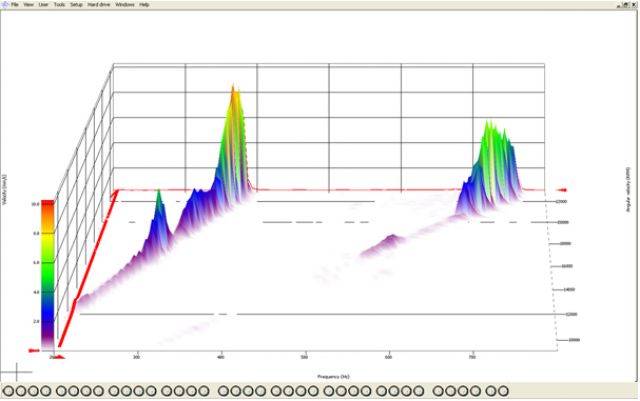

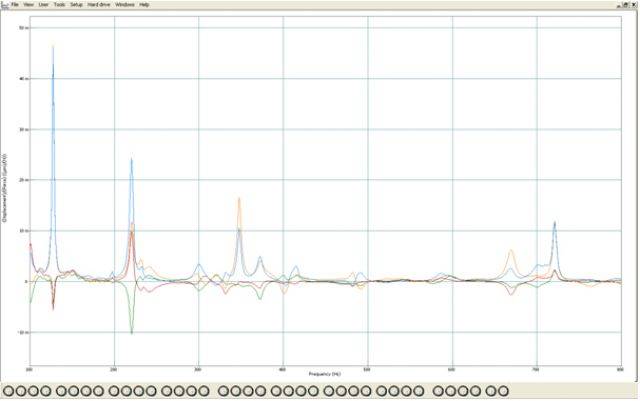

Vibration analysis

Analysis of vibration recordings: spectral analysis, determination of critical speeds, failure pre-diagnosis, anomaly detection.

Inspection and diagnosis with system balancing

Failure analysis, operating tests, diagnosis. Balance checking in our factory and on site.

Curative and preventive maintenance of mechanical equipments

Competence in the field of preventive and curative maintenance of mechanical equipment. Establishment of maintenance procedures.

Mechanical equipment design from an analysis of the customer’s needs

Taking into account customer’s requirements and joint development of technical specifications defining the characteristics of the need and the customer’s expectation in terms of performance.

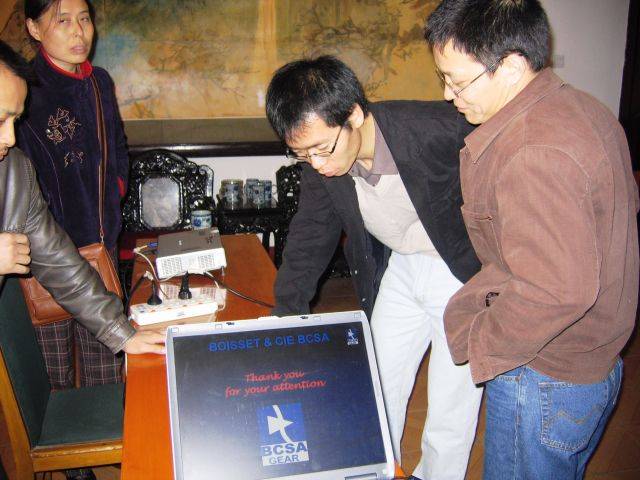

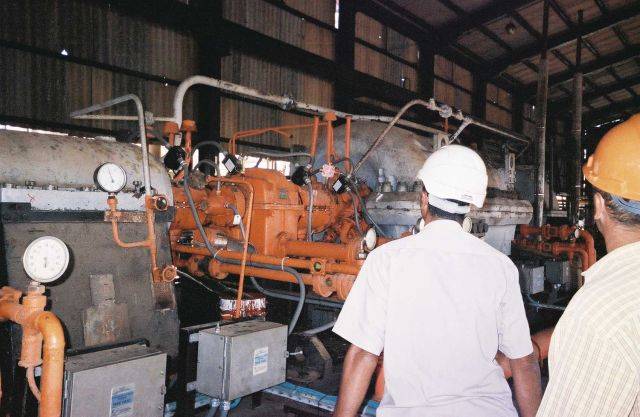

On-site recording (vibration, temperature, …)

We take action on site to make recordings of vibration data and temperature readings. Our engineers are equipped with efficient portable equipment capable of recording simultaneous 12 dynamic channels.

Measurement analysis

Recordings made on-site are analysed and processed in our factory with powerful processing and analysis software. An analysis report is drawn up and passed to the customer with recommendations concerning any necessary preventive or curative maintenance.

On-site inspection and diagnosis

Our maintenance engineers are available 365 days a year for an inspection or diagnosis on any mechanical assembly. The intervention may also include a campaign of measurements on site.

On-site intervention

Our maintenance engineers and technicians are available 365 days a year for an inspection or diagnosis on-site, or to install and commission our equipment

Service provision and interventions:

- Installation

- Commisionning

- Inspection et diagnosis

- Balancing

- Vibration analysis

- Curative et préventive maintenance

Our strengths:

- Understanding and taking account of the needs of our customers

- Installation of real time measuring and recording equipment, dynamic and data channels

- Vibration measurement analysis speciality team

- Inspection and diagnosis of operating machines on site.

- On-site intervention teams, implementation of preventive maintenance procedures.

Our references : AIRBUS, ALSTOM, Ciments Français, DASSAULT Aviation, EADS, ECDE, ERCC, ERCE, ERCO, EUROCOPTER, HISPANO-SUIZA, INEOS, ITP, LAFARGE, ONERA, RENAULT F1, SAFRAN, SONATRACH, THALES, TOTAL, TURBOMECA, ZODIAC.

Contact us for more details